Reliable Hardware Expert

Beijing iTulipu Technology Co., Ltd. is a one-stop hardware solutions provider with over 10 years of experience in delivering end-to-end product development services.

Over the past decade, we have made continuous investments in R&D and talent development, enabling us to deliver cutting-edge solutions. Our commitment to innovation and quality has earned the trust of over 300 customers worldwide, many of whom have built lasting partnerships with iTulipu.

To date, iTulipu holds 4 self-developed patents, 11 software copyrights, and has 8 additional patents currently under application.

We offer complete, customized hardware solutions covering the entire product lifecycle — from product design (ID/MD and full-device evaluation), to R&D (PCB, SI/PI, DFM, and ODM), to testing (EMC, environmental, and reliability), and all the way through production (supply chain management, prototyping, and mass manufacturing).

PCB Layout Capabilities

At iTulipu we specialize in high-precision PCB layout design, ensuring your boards are optimized for performance, reliability, and manufacturability. With years of experience, our team excels in creating complex layouts for multi-layer boards, high-speed circuits, and high-frequency designs.

We use advanced PCB design tools to handle intricate layouts, maintaining signal integrity, minimizing noise, and ensuring proper power distribution.

Whether it’s a simple single-layer board or a high-performance multi-layer PCB, we apply rigorous design rules to ensure optimal routing, minimizing cross-talk, and enhancing thermal performance. Our thorough design review process includes DFM (Design for Manufacturability) checks, ensuring that your design can be efficiently produced at scale.

DESIGN IT WITH USPCB Layout Workflow

iTulipu specializes in high-performance PCB layout, with over 15 years of engineering experience in high-speed, high-density designs. We focus on signal integrity, power optimization, and manufacturability, supporting complex, multi-layer boards across diverse applications. Our team ensures precision, efficiency, and full design rule compliance throughout the layout process, helping you accelerate development with confidence.

Rapid Prototype

PCB Fabrication

Paper food boxes and take out containers – durable heavy gauge made from sustainable plant resources.

Get a free quote

PCB Manufacturing

Advanced PCB Manufacturing & Rapid Delivery

iTulipu provides high-end PCB manufacturing services, covering high-layer-count boards (up to 20+ layers), high-speed and high-frequency PCBs, HDI boards, rigid-flex PCBs, metal core boards, and heavy copper PCBs. We specialize in the rapid production of complex, multi-layer, and high-speed designs, with prototype lead times as fast as 2–7 working days.

Our manufacturing lines are optimized for flexibility, supporting multi-variety prototypes, small batches, and mid-volume production runs. This agile approach allows us to meet critical testing, validation, and early-stage production needs, helping you shorten R&D cycles and speed up time-to-market.

Start Your Project

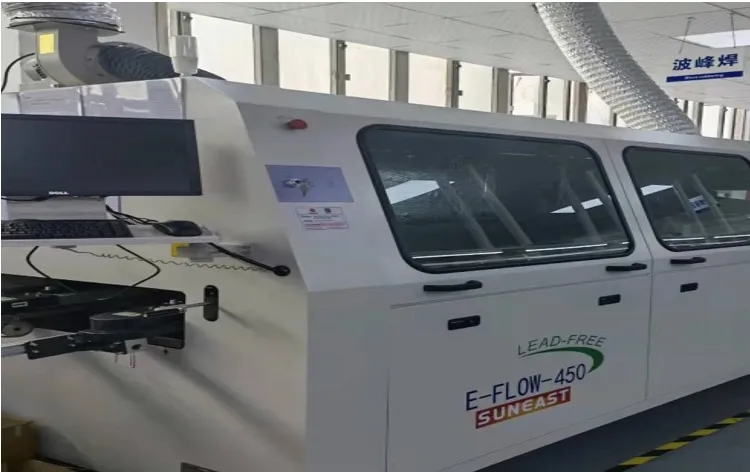

SMT Welding

Industries We Serve

iTulipu offers end-to-end hardware solutions with a strong focus on PCB design, PCB layout, rapid prototyping, testing, debugging, and certification support. We serve clients in consumer electronics, industrial automation, medical devices, and IoT-based energy systems. From concept to production, we ensure speed, quality, and global compliance. Backed by 10+ years of experience and 300+ international clients, we support both startups and enterprises with flexible, high-reliability engineering services.

Consumer & Lifestyle Electronics

We provide PCB design for smartphones, smart appliances, and AI devices, with expertise in high-speed, high-frequency, and high-density layouts — ensuring performance and reliability for advanced consumer electronics.

Industrial & Automotive Applications

We design reliable PCBs and embedded systems for industrial control, supporting harsh environments, long lifecycles, and precise signal integrity. Our experience includes automation, sensors, and industrial communication — ensuring stability, durability, and high performance in critical applications.

Medical & Health Tech

We develop PCBs for medical and health tech devices, including wearables, monitors, and diagnostic tools. Our designs meet strict reliability, safety, and regulatory standards, supporting accurate signal processing and long-term performance in health-critical applications.

IoT, Communication & Energy Systems

We design hardware for IoT, communication, and energy systems, including smart meters, gateways, wireless modules, and power controllers. Our expertise covers low-power design, wireless protocols (LoRa, NB-IoT, Wi-Fi), and EMC compliance — enabling secure, reliable, and scalable connected devices.

Why Choose iTulipu as Hardware Partner

One-Stop Hardware Solutions

From design to mass production — we handle it all, so you don’t have to juggle multiple vendors. From product design to prototyping, testing, certification, and mass production — all under one roof for maximum efficiency and speed.

Trusted Engineering Expertise

10+ years of experience, 300+ satisfied clients, and a team that knows how to deliver.Backed by experience at industry giants like Nokia, Microsoft, and Honeywell, our core engineers bring enterprise-grade quality and innovation to your product.

Fast, Flexible, and Scalable

Quick prototyping, strong supply chain, and seamless transition to high-volume production. We combine in-house pilot lines with trusted manufacturing partners to scale quickly from prototyping to mass production — with full control over speed, quality, and cost.

Global-Ready & IP-Safe

We meet international standards, hold multiple patents, and ensure your intellectual property is protected. Our team supports major design software, offers direct engineer-to-client communication, and helps your product meet certifications like CE, FCC, UL, and EMC.

Our Labs and Production Lines

Projects We’ve Built

Real-world products we’ve designed, prototyped, and delivered across industries—from consumer electronics to industrial and IoT systems.

Our Partner

Pre-Sales & After-Sales FAQ

Please share your schematic, design files, BOM, and expected quantity. If available, also include mechanical drawings or performance requirements.

We sign NDAs and strictly follow internal IP protection procedures. Your design data is safe with us.

We support all major PCB design platforms and can adapt to your workflow for seamless collaboration.

Our engineers will help identify issues, suggest modifications, and assist with re-testing until the product passes.

SPlease contact our support team within 7 days of delivery. Share clear photos or videos of the issue, and we’ll investigate and provide a replacement, repair, or refund based on our warranty terms.

We offer a standard 12-month warranty for PCB manufacturing and assembly defects. For ODM or full-product builds, warranty terms may vary based on project agreement.

Yes, our engineering team provides post-delivery debugging, layout review, and performance analysis support if needed. We aim to help you improve reliability and reduce time-to-market.

We will work with you to identify the cause, adjust the design or layout, and help re-test to meet CE, FCC, UL, or EMC certification standards.

Absolutely. Our team continues to support you during pilot runs and mass production, including BOM optimization, DFM updates, and quality tracking.

Yes. We provide priority email and phone support for urgent technical or production-related issues, especially during ramp-up or delivery phases.

Of course. We can resend all relevant documents, including Gerbers, test reports, and inspection records, upon request.

If your project includes embedded firmware or driver-level software, we offer limited post-delivery updates or bug fixing within the agreed support period.